I love exploring the world of fragrances. The perfume industry fascinates me because it blends art and science. Many people ask, “How perfume is made?” or “How is cologne made?” I see this question come up a lot. Perfume production involves multiple steps. It starts with a concept and ends with a final product. Experts call this the perfume manufacturing process.

Perfume production grew from ancient practices. People used flowers, spices, and oils to create scents. Over time, new methods made things more efficient. Now, perfume manufacturing involves global trade, modern machinery, and skilled perfumers. I view this industry as a huge network of creativity and technology. It requires careful planning and a deep understanding of ingredients.

Industry Overview

The perfume industry thrives worldwide. Major brands create scents for every preference. Niche perfumers also emerge with unique approaches. Fragrance production involves cologne manufacturing, perfume making, and other scent-based products. Companies source raw materials, formulate blends, and bottle these fragrances.

People want to know what is perfume, where is perfume made, and how are perfumes made step by step. Some fragrances come from small artisan labs. Others emerge from large factories with advanced tools.

From Concept to Launch

Perfumers begin with a vision. They imagine a mood or style. They sketch a fragrance profile with top, middle, and base notes. Each layer offers a different scent experience. Brands then refine these ideas. They consider market trends and brand identity. When they finalize the concept, they work on the actual perfume making process.

Perfumers choose suitable raw materials. They use essential oils, extracts, and aroma chemicals. They test each ingredient for quality and scent profile. Then they blend small trial batches.

After that, they evaluate how the perfume smells over time. I hear many people ask, “How do they make perfume, and what is perfume made out of?” The answer involves both natural and synthetic components. Natural oils offer complexity. Synthetic molecules add stability.

Final Product

Once they settle on the formula, they move to larger-scale fragrance manufacturing. This stage involves advanced equipment. Experts blend essential oils, fixatives, and alcohol. They test the mixture’s fragrance quality, color, and consistency. Quality control officers confirm that each batch meets strict standards. Then bottling occurs. The result: cologne, perfume, or other scented products.

Market Growth

Perfume production continues to grow. Designers launch limited editions. Indie perfumers experiment with rare botanicals. Technology streamlines processes like packaging and distribution. I see new brands appear each year. This cycle fuels the evolution of fragrance creation.

Today, the question “How was perfume made in the past?” has turned into “How do people make perfume for modern tastes?” The perfume industry answers both. It respects time-honored traditions. It also embraces cutting-edge innovation.

When someone asks, “How is perfume made step by step?” I explain that it’s a journey. It starts with an idea, passes through fragrance production, and ends with a bottle of scent that tells a story.

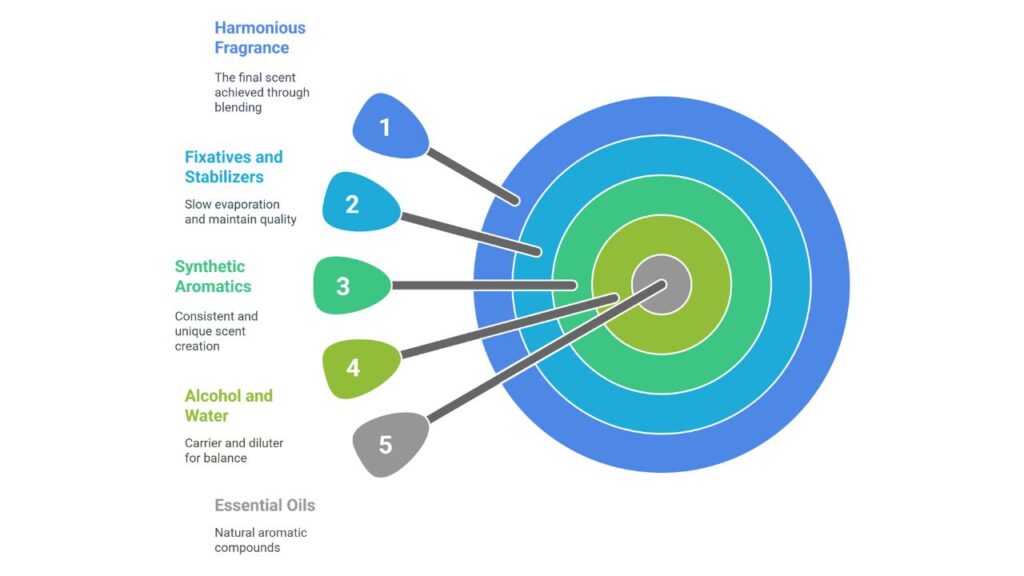

Key Ingredients in Perfume Making

I always enjoy learning about the building blocks of a scent. When someone asks, “What is perfume made of?” I point to its core ingredients. Perfume blends essential oils, alcohol, and water. It may also contain synthetic aromatics. Each element plays an important role in how cologne is made.

| Ingredient | Role in Perfume |

|---|---|

| Essential Oils | Provide natural aromatic compounds |

| Aroma Chemicals | Offer specific scent notes and increase stability |

| Alcohol (Ethanol) | Serves as a carrier and helps diffuse the fragrance |

| Water | Balances the formula and adjusts intensity |

| Fixatives | Anchor the scent and slow evaporation |

Essential Oils

Essential oils come from flowers, fruits, leaves, and roots. Rose and jasmine oils add floral notes. Citrus oils like bergamot or lemon add freshness. These oils deliver the main fragrance. People often wonder, “How are perfume oils made?” The answer involves methods like steam distillation or cold pressing. Traditional perfumers rely on these oils for depth and complexity.

Alcohol and Water

Alcohol boosts the scent’s projection. It helps the fragrance spread. I see many perfumers use ethanol because it evaporates quickly and leaves behind the scent. Water dilutes the mixture. It ensures the scent does not become too potent. This balance creates the perfume’s final aroma profile.

Synthetic Aromatics

Some ask, “What is cologne made out of if not only natural oils?” Synthetic molecules help perfumers design unusual scents. They also offer consistent results. Natural harvests can vary each year. Synthetic compounds fill that gap. They produce stable fragrance notes. This consistency matters in cologne manufacturing.

Fixatives and Stabilizers

Fixatives bind the scent to your skin and slow evaporation. Materials like musk or ambergris acted as traditional fixatives. Modern perfume manufacturing often uses synthetic fixatives. Stabilizers keep the fragrance formula safe over time. They reduce color changes and preserve scent quality.

Choosing Ingredients

Brands decide which ingredients fit their vision. Some prefer an all-natural approach. They might use organic oils. Others combine natural and synthetic materials. That method adds durability and unique aroma profiles. When people ask, “Which organic compounds are often used to create fragrances for the perfume industry?” I list things like terpenes (from citrus) and phenyl ethyl alcohol (from roses).

Significance of Quality

High-quality raw materials shape perfume success. Low-grade oils can make the final product smell off. Impurities can cause skin irritation. Reputable perfume houses prioritize purity and safety. They follow regulations and maintain standards.

Understanding the role of each ingredient explains how perfumes are made. It also clarifies how colognes are made. When people ask, “How do you make perfume?” I say it begins with top-notch components. Then, experts blend them to form a harmonious fragrance.

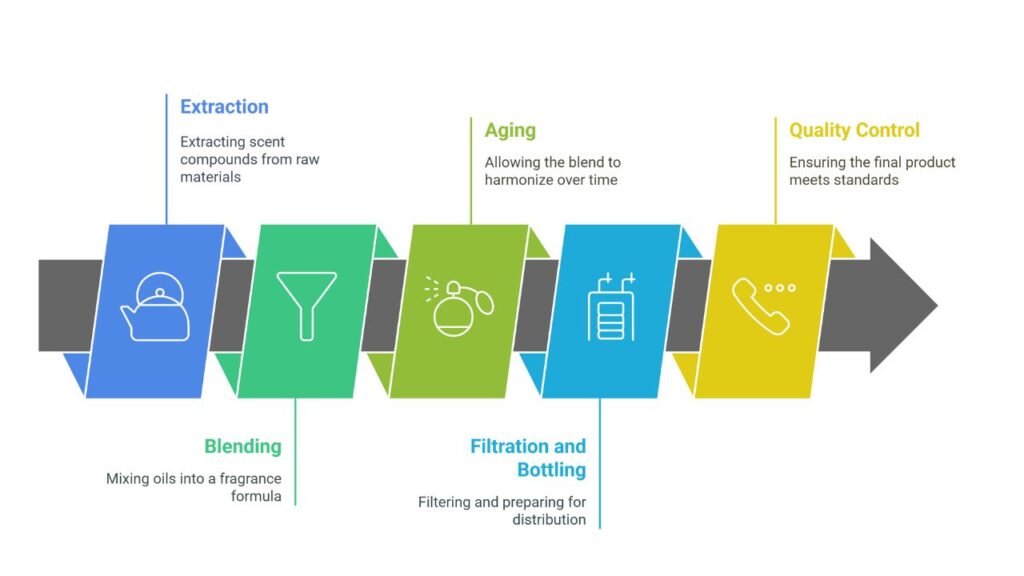

The Perfume Making Process

I often guide friends through the journey of perfume creation. Many people wonder, “How is perfume made step by step?” or “How do they make cologne in modern labs?” This perfume making process combines tradition and innovation. It includes extraction, blending, and aging.

1. Extraction

Extraction pulls scent compounds from raw materials. I group extraction into several methods:

- Steam Distillation: Producers pass steam through botanical matter. The steam carries aromatic molecules. Then they cool it to separate the oil.

- Solvent Extraction: Factories soak flowers or other materials in solvents. They later remove the solvent. The result is a waxy substance called concrete, which they turn into absolute.

- Expression: This works for citrus peels. Machines press or grate the peels to release aromatic oils.

When people ask, “How was perfume made in past centuries?” I mention that steam distillation was a classic method. Modern cologne manufacturing also uses it.

2. Blending

Perfumers take extracted oils or aroma chemicals and mix them into a formula. They measure each component precisely. They consider top, middle, and base notes. Top notes greet your nose first. Middle notes form the fragrance’s heart. Base notes linger the longest.

I compare this to cooking. A chef balances spices, salt, and sweeteners. A perfumer balances floral, spicy, and woody accents. This stage answers the question, “What is perfume made from?” It depends on the brand’s vision. A bright citrus scent might blend lemon and bergamot with light florals. A richer perfume might layer rose, patchouli, and musk.

3. Aging

Perfumers let the blended oils rest in alcohol. This step harmonizes the fragrance. It smooths rough edges. Sometimes I see perfumers age their mixtures for several weeks or months. This process helps each note meld with the others. Aging plays a key role in how perfumes are made.

After aging, brands test the scent. They check how it dries down on skin. They confirm that top notes pop and base notes last. Some refer to this as fragrance evaluation. If something seems off, perfumers adjust the formula and age it again.

4. Filtration and Bottling

Once they achieve the desired scent profile, they filter the mixture. This removes any sediment or impurities. Then they move on to bottling. Many people ask, “How do people make perfume at large scales?” Factories use automated lines. They fill, seal, and label bottles quickly. This step completes the fragrance production.

5. Quality Control

Brands run final checks. They confirm that each batch meets the same standards. They test scent, color, and packaging. They also follow rules for safety. Some wonder, “Is perfume a mixture?” Yes, it is. It is a mixture of fragrant oils, alcohol, water, and other compounds.

This process brings the perfumer’s vision to life. Each stage builds on the one before it. From raw materials to the final spritz, perfume making represents a careful blend of art and science.

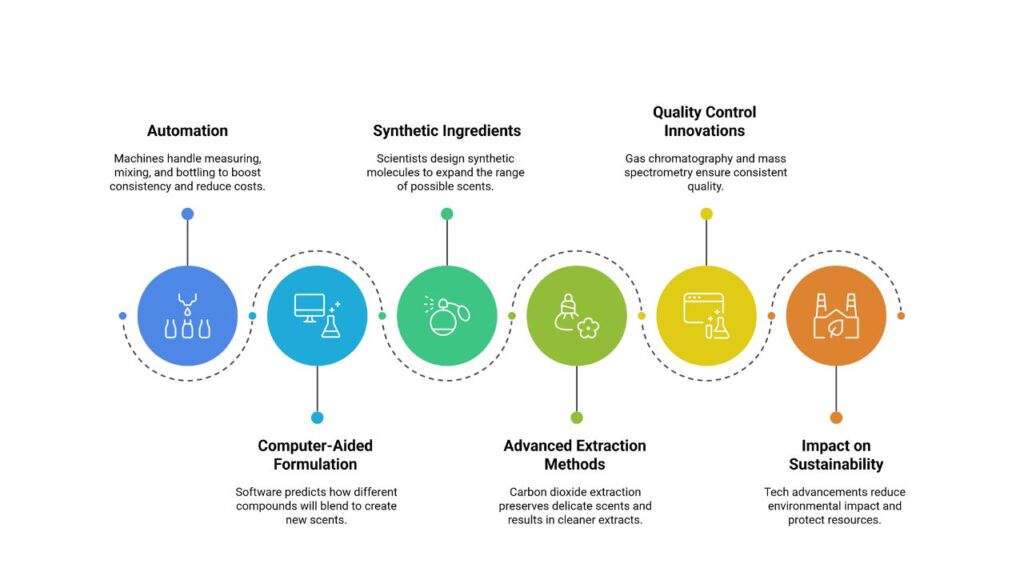

Technological Advances: How Perfume Is Made

I embrace the changes that technology brings to fragrance manufacturing. People often ask, “How are fragrances made today compared to the past?” or “How do they make perfume in high-tech labs?” Modern equipment and synthetic ingredients have transformed the industry.

Automation

Large-scale perfume manufacturing plants rely on automation. Machines handle measuring, mixing, and bottling. This approach boosts consistency. It reduces errors. I have watched videos of robotic arms capping bottles at lightning speed. Automation saves time and lowers costs. It also improves safety.

Computer-Aided Formulation

Some perfumers use software to create new scents. This software predicts how different compounds will blend. It speeds up fragrance making. It also helps them match existing scents when they want to create a similar product. For instance, if a perfumer wants to replicate a classic floral arrangement, software can estimate the right mix of essential oils and aroma chemicals.

Synthetic Ingredients

Scientists design synthetic molecules that capture unique aroma profiles. They often tweak natural structures or create entirely new chemicals. These molecules expand the range of possible scents. I find it amazing that these new compounds sometimes smell like natural raw materials that are hard to source. They also boost sustainability. Some ask, “What is used to make perfume if certain flowers grow scarce?” Synthetic options address that problem. They lessen the strain on wild plant species.

Advanced Extraction Methods

Tech improvements also influence the raw material stage. Carbon dioxide extraction uses pressurized CO₂ to pull aroma compounds from botanicals. This method avoids chemical solvents. It preserves delicate scents. It also results in cleaner extracts.

Quality Control Innovations

Modern labs use gas chromatography and mass spectrometry. These tools break down a scent’s components. They show exact proportions of each compound. Perfumers confirm that they meet the brand’s requirements. This data helps them ensure consistent quality with every batch.

Impact on Sustainability

Tech advancements reduce environmental impact. Automated systems lower waste. Synthetic molecules protect endangered resources. Some fragrance houses use solar or wind power in their factories. Others experiment with biodegradable packaging. People want to know how cologne is made without harming the planet. Technology can address those concerns.

Conclusion

When I see new trends, I realize how far we have come from ancient distillation pots. Fabrication de parfum has embraced cutting-edge methods. Perfume manufacturing merges craftsmanship with modern science. That synergy drives cologne manufacturing forward. It also encourages more brands to explore ethical sourcing and innovative techniques.

How Fragrances Are Designed and Tested?

I enjoy explaining how perfumers design and test new fragrances. When people ask, “How do you create a perfume from scratch?” I walk them through these stages. It starts with an idea and ends with rigorous evaluation.

Initial Scent Concept

Perfume houses begin with a theme or mood. Maybe it’s a fresh oceanic vibe. Or perhaps a deep and spicy winter blend. They outline the scent structure. They choose notes that communicate this mood. They consider how the final user will experience it. This stage helps them decide, “What is perfume made out of for each layer?”

Pilot Batches

Once they finalize the concept, perfumers craft small trial batches. They mix essential oils, aroma chemicals, and fixatives. They tweak proportions until they like the result. They compare versions to see which one smells closest to their vision. I treat these trials like test recipes. They are quick and easy to adjust.

Stability Testing

Perfumers test how well the fragrance holds up. They expose samples to heat, light, and air. They note if the color changes or if the scent weakens. They also monitor if any sediment forms. Stability testing ensures that the perfume remains consistent over its shelf life. People often ask, “How does perfume work months or even years after purchase?” Stability testing answers that question.

Olfactory Evaluation

Perfume experts smell the samples over time. They check how the top notes fade and how the base notes linger. They gather feedback from panels of testers. These testers share impressions: Is the scent too sharp? Does it feel balanced? Do the middle notes match the brand’s idea?

Adjustment and Finalization

After each round of evaluation, perfumers adjust the formula. They might reduce one note or increase another. This process can last weeks or even months. Some big brands run multiple rounds until they reach perfection.

Validation

After final adjustments, the brand produces a bigger batch. They confirm that the scent matches the pilot blend. They do another round of checks. If everything looks good, they move to large-scale production.

Every step in fragrance design and testing aims for quality. It ensures that cologne manufacturing runs smoothly. It explains how perfumes are made in a precise and reliable way. When people ask, “How do you make perfume that stays consistent?” I always mention thorough testing. It guarantees that each bottle smells exactly as intended.

Challenges in Perfume Manufacturing

I see many hurdles that perfumers face today. People often ask, “What are the hardest parts of the perfume making process?” or “How do they make perfume under strict regulations?” Challenges span ingredient sourcing, maintaining consistency, and meeting legal rules.

Ingredient Sourcing

Perfume manufacturing depends on high-quality materials. Essential oils vary by climate and harvest. One season of rose petals may smell different from another. This variation can alter how the final fragrance performs. Global supply chains add more pressure. Delays and price spikes affect cologne manufacturing.

Some materials are rare or endangered. Oud, derived from agarwood, exemplifies this scarcity. Ethical brands try to ensure sustainable harvesting. They also rely on synthetic alternatives. This approach addresses the question, “What is cologne made out of if the natural source is protected?” However, switching to synthetics sometimes changes the fragrance profile. That creates a balancing act.

Case Example: Rose Oil Variability

I have seen big fragrance houses struggle with rose oil supply. Weather or regional conflicts can cut supply. Prices rise, and the brand must find a replacement. That new source may smell slightly different. Perfumers then adjust the formula. They add complementary notes to maintain the brand’s signature.

Consistency

Customers expect consistent scents. They want each bottle to smell the same. Perfume production involves mixing many compounds. If the ratio shifts, the scent changes. Machinery helps measure ingredients precisely. Even so, raw materials can differ in aroma strength.

Perfumers use standardized extracts or synthetic ingredients to combat this. They rely on methods like gas chromatography to confirm the exact chemical makeup. This technology helps them spot minute variations. Quality control labs also store “golden” reference batches. They compare each new batch against these.

Regulatory Compliance

I notice how various regions enforce strict rules on fragrance ingredients. Europe has regulations that limit certain allergens in perfumes. The United States requires listing specific components. Other countries have unique guidelines. Perfumers must comply with these rules to sell products internationally.

This compliance challenge touches many aspects. Packaging labels must list certain ingredients. Some natural extracts contain allergens that must be declared. Shipping flammable materials like alcohol-based fragrances also requires permits.

Safety Testing

Brands must test for skin irritation. They follow safety protocols to ensure consumers do not experience harm. If they find a problematic ingredient, they reformulate. That leads to changes in how colognes are made. It also means more steps in the process of making perfume.

Rising Costs

High-quality essential oils cost more each year. Land for growing certain botanicals remains limited. Transportation costs also rise. Factories invest in high-tech machinery for better precision. All these factors drive up the final price. This affects small artisan perfumers the most. They face tough competition from larger brands that can negotiate bulk rates.

Market Trends and Brand Identity

Brands must keep up with changing trends. Consumers want new scents that match the season. They also demand transparency. They ask, “Where does perfume come from?” and “What is fragrance made of?” This pressure means brands must share their sourcing strategies. They must also explain their production methods.

Balancing Art and Science

Perfumers juggle creativity with practicality. They want to stand out. They also need to follow safety rules and meet budget constraints. This tension pushes perfumers to innovate. They might discover new ways of blending or advanced fixatives. They might also adopt organic practices or more eco-friendly packaging.

Global Competition

Perfume production faces competition from all corners of the globe. Niche houses challenge mainstream giants. Internet retailers let small brands reach large audiences. This competition drives brands to refine their craft. They must create unique fragrances that capture attention.

Conclusion

I see these challenges shaping the perfume industry’s future. Ingredient sourcing demands sustainability. Consistency relies on advanced testing. Regulatory rules protect consumers. At the same time, rising costs push innovation. This process is ongoing. When people ask, “How is perfume made step by step in modern times?” I explain each stage. I also mention these hidden hurdles. Together, they make the fragrance world complex and exciting.

DIY Perfume Making

I love experimenting at home with simple DIY methods. Many friends ask me, “How do you make perfume in your own kitchen?” or “How make perfume with a personal twist?” Here is a basic guide.

Tools and Ingredients

- Essential Oils: Choose scents you enjoy. Lavender, rose, vanilla, or citrus all work well.

- Carrier Alcohol: High-proof vodka is common. Some people use perfumer’s alcohol.

- Distilled Water: Balances the blend and helps mellow strong scents.

- Glass Bottles or Vials: Use dark-colored bottles to protect the oils from light.

Simple Recipe

- Gather your favorite essential oils. For a floral perfume, pick rose (top), jasmine (middle), and sandalwood (base).

- Add about 30 drops of combined essential oils to a small glass bottle.

- Pour in 2 tablespoons of vodka.

- Shake the bottle gently. Store it in a cool, dark place for a couple of days.

- Add 1 tablespoon of distilled water. Shake again. Let it sit for another day or two.

- Filter the mixture if needed. Store your homemade cologne in a dark bottle.

Tips for Success

- Start with fewer drops of essential oil. You can always add more.

- Keep notes of how many drops you use. That helps you recreate blends later.

- Experiment with layering top, middle, and base notes. That approach adds depth.

Why DIY?

DIY perfume helps you explore fragrance making without huge costs. It also teaches you about how fragrances are made. You pick safe, natural ingredients. You learn how do people make perfume by hand. This hands-on process gives you a personal scent.

If you want to advance, you can look into specialized equipment. You can learn how to make perfume professionally. But a simple approach works fine for beginners. Just remember that homemade perfumes sometimes have shorter shelf lives. Store them properly and enjoy your unique creation.

Future Trends in Perfume Making

I get excited when I consider where fragrance production may go next. Experts predict many changes. People ask, “What does the future of making fragrances look like?” Sustainability, innovation, and consumer demands all influence new directions.

Sustainability

Many brands focus on eco-friendly materials. They source botanicals from farms that care for the land. They invest in refillable or biodegradable packaging. More consumers want to know how cologne is made without harming the environment. This push toward greener practices will grow.

Biotechnology and Lab-Grown Ingredients

Researchers explore lab-grown fragrance molecules. Some methods involve genetically modified yeast or bacteria. These organisms produce scent compounds. This approach reduces pressure on wild plants. It may also lower costs. I see potential for new exotic notes.

Personalization

Companies experiment with custom scents. They use AI or advanced diagnostics to match fragrances to body chemistry. Imagine walking into a store, scanning your skin pH, and receiving a tailored perfume formula. This personalized approach might become more common.

Virtual Reality and Digital Tools

Some brands test VR experiences. They let you explore scent profiles before you smell them in person. Designers can adjust virtual notes on the spot. This technology speeds up the creative process. It also offers an interactive experience for customers.

Minimalist and Health-Focused Products

People care about the ingredients they place on their bodies. Fragrance manufacturing will likely see more lines labeled “clean” or “low allergen.” Perfume houses might reveal more about each compound they use. Transparency builds trust.

Conclusion

I believe the perfume industry will keep evolving. People seek new experiences. They also care about the planet. Technology offers new extraction methods and manufacturing options. When I think about “how is perfume made” in the future, I imagine balanced blends of science, nature, and creativity. This synergy will shape perfumes for decades to come.